Conclusions

-

1.

The second stage of creep in heat-resistant nickel alloys is due to changes in their intercrystalline structure.

-

2.

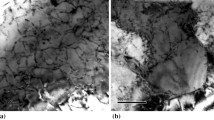

With the same creep rate during the entire second period, which is characteristic of heat-resistant alloys containing a moderate amount of hardening phase equally distributed in the matrix, deformation is due to the gradual propagation of individual dislocations, leading to crystalline slip.

-

3.

In alloys containing a substantial quantity of hardening phase creating a field of elastic distortion the deformation develops unevenly-the second state of creep has several sections with constant but differing rates of deformation. Each section is characterized by a different mechanism of the interaction of dislocation with growing particles of the hardening phase.

-

4.

The low creep rate in the first section for alloy ÉI661 is due to pinning of dislocations around particles of γ′ phase; accelerated creep in the second section is due to the higher density of mobile dislocations; proparation of dislocations prevents particles of γ′ phase from growing together into platelets in the third stage with a lower creep rate.

Similar content being viewed by others

Literature cited

L. N. Zimina, S. B. Maslenkov, and I. M. Trakhimovich, "Kinetics of the aging process in heat-resistant nickel alloys," in: Electron Microscopic Study of the Structure of Heat Resistant Alloys and Steels [in Russian], Metallurgiya, Moscow (1969), p. 30.

Yu. D. Tyapkin, N. T. Travina, and V. P. Kozlov, "Electron microscopic investigation of the parameters of the three-dimensional distribution of second phase in aging nickel-base alloys," Fiz. Met. Metalloved.,35 No. 3, 577 (1973).

L. N. Zimina, "Structure and properties of alloy ÉI661 after prolonged testing," in: Special Steels and Alloys [in Russian], No. 52, Metallurgiya, Moscow (1967), p. 95.

I. I. Novikov, Lattice Defects in Metals [in Russian], Metallurgiya, Moscow (1975), p. 146.

V. M. Nosevich (editor), Electron Microscopic Images of Dislocations and Stacking Faults Handbook [in Russian], Nauka, Moscow (1976), p. 104.

H. Gleiter, Acta Met.,16, 455 (1968).

B. Ya. Lyubov and V. A. Shmakov, "Theory of diffusional interaction of edge dislocations with precipitates of new phase," Fiz. Met. Metalloved.,29, 978 (1970).

Additional information

I. P. Bardin Central Scientific-Research Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 35–39, November, 1979.

Rights and permissions

About this article

Cite this article

Travina, N.T., Nikitin, A.A. & Zimina, L.N. Dislocation arrays formed during creep of heat-resistant nickel alloys. Met Sci Heat Treat 21, 855–860 (1979). https://doi.org/10.1007/BF00708353

Issue Date:

DOI: https://doi.org/10.1007/BF00708353