Abstract

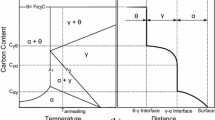

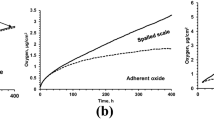

Several austenitic heat-resistant steels were exposed to alternating periods of carburization at 1273 K [a c= 1,po2<10−28 atm] and oxidation at 973°K [a c≈ O,po2 = 0.2 atm]. In all cases the depth of internal carbide precipitation increased with cumulative carburization time. It was found that the carburization rates of high nickel content alloys were unaffected by intermittent oxidation cycles, whereas the low nickel, high iron content alloys experienced a reduction in carburization rate subsequent to oxidation treatment. The latter group of alloys formed external scales of chromium-rich M7C3 which were shown by sulfur tracing experiments to be gas permeable. It was concluded, therefore, that oxidation of these materials led to blockage of cracks and holes in the scales, thereby decreasing the surface carbon activity and hence the carburization rate. High nickel, low iron alloys formed external scales of chromium-rich M7C3 covered by Cr3C2. These scales were shown to have very low gas permeabilities. It was concluded that the carbon activity at the surface of these alloys was controlled by scale-alloy equilibration, and was therefore not affected by brief periods of oxidation. The pattern of carbide scale formation is qualitatively consistent with the thermodynamics of the Fe-Cr-C system.

Similar content being viewed by others

References

H. Lewis,Br. Corros, J. 3, 166 (1968).

A. Schnaas and H. J. Grabke,Oxid. Met. 12, 387 (1978).

K. Ledjeff, A. Rahmel, and M. Schorr,Werkst. Korros. 31, 83 (1980).

M. J. Bennett and J. B. Price,J. Mater. Sci. 16, 170 (1981).

R. Kane,Corr. 37, 187 (1981).

G. H. Meier, W. C. Coons, and R. A. Perkins,Oxid. Met. 17, 235 (1982).

G. M. Smith, D. J. Young, and D. L. Trimm,Oxid. Met. 18, 229 (1982).

T. A. Ramanarayanan and R. Petkovic-Luton, inHigh Temperature Corrosion, R. A. Rapp, ed (NACE, Houston, 1983), p. 430.

P. J. Smith, O. Van der Biest, and J. Corish,Oxid. Met. 24, 47 (1985).

H. J. Grabke, R. Möller, and A. Schnaas,Werkst Korros. 30, 794 (1979).

J. Barnes, J. Corish, F. Franck, and J. F. Norton,Oxid. Met. 24, 85 (1985).

P. Tomaszewicz, P. R. S. Jackson, D. L. Trimm, and D. J. Young,J. Mater. Sci. 20, 4035 (1985).

P. R. S. Jackson, D. L. Trimm, and D. J. Young,J. Mater. Sci. in press.

Y. Ikeda and K. Nii,Oxid. Met. 12, 487 (1978).

C. Wagner,Z. Electrochem. 63, 772 (1959).

R. A. Rapp,Corr. 21, 382 (1965).

F. Maak,Z. Metallkunde,52, 545 (1961).

H. J. Goldschmidt,Interstitial Alloys (Plenum Press, New York, 1967). pp 94–95.

P. Tomas, D. J. Young, and D. L. Trimm,Proceedings of the 9th International Congress on Metallic Corrosion (National Research Council of Canada, Ottawa, 1984), Vol. 1, pp. 58–65.

R. Benz, J. F. Elliott, and J. Chipman,Met. Trans. 5, 2235 (1974).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kinniard, S.P., Young, D.J. & Trimm, D.L. Effect of scale constitution on the carburization of heat resistant steels. Oxid Met 26, 417–430 (1986). https://doi.org/10.1007/BF00659345

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00659345