Summary

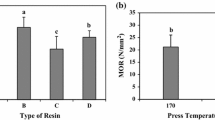

To better understand the curing and bonding behavior of phenol-formaldehyde (PF) resin under dynamic conditions, flakeboards were manufactured either by conventional pressing at 7% or 12% mat moisture content or by steam injection pressing with 10 or 20 seconds steaming duration. Resin-impregnated glass-cloth samples and lap-shear tension specimens were embedded in the core of each flakeboard. After the flakeboards were pressed for various periods of times, the samples and specimens were quickly retrieved. The degree of resin cure was determined on the resin-impregnated glass-cloth samples by dynamic mechanical analysis. The bond strengths were measured from the lap-shear tension specimens on a mechanical testing machine. The results of resin curing and bonding were then correlated to the performance of the resin-bonded boards, which were evaluated by internal bond, modulus of rupture, modulus of elasticity, and thickness swelling. Resin curing and lap-shear bonding did not proceed simultaneously. In conventional pressing, the mat moisture content (MC) at 12% favored resin curing, but slightly retarded lap-shear bonding, as compared to 7%MC. In steam injection pressing, the rates of resin curing and lap-shear bond strength development were much faster for 20 seconds than for 10 seconds of steaming duration. Longer press times were needed to obtain boards with maximum strength in the 12%MC conventional pressing and the 20-s steam duration steam injection pressing than in those conditions where moisture content was lower or steam time was less. The need for longer press times must be attributed to higher internal vapor pressures and/or lower wood and resin component strengths, rather than to incomplete cure or bonding.

Similar content being viewed by others

References

American Society for Testing and Materials. 1970: Standard methods of evaluating the properties of wood-based fiber and particle panel materials. ASTM Standard Designation: D1037-64. Philadelphia, PA

Back, E. L.; Salmén, N. L. 1982: Glass transitions of wood components hold implications for molding and pulping processes. Tappi 65(7): 107–110

Casey, L. J. 1987: Changes in wood flake properties in relation to heat, moisture, and pressure during flakeboard manufacture. M.S. thesis, Virginia Polytechnic Institute and State University, USA

Chow, S.-Z. 1969: A kinetic study of the polymerization of phenol-formaldehyde resin in the presence of cellulosic materials. Wood Sci. 1: 215–221

Chow, S.-Z.; Hancock, W. V. 1969: Method for determining degree of cure of phenolic resin. Forest Prod. J. 19: 21–29

Chow, S.-Z; Mukai, H. N. 1972: Polymerization of phenolic resin at high vapor pressure. Wood Sci. 5: 65–72

Christiansen, A. W.; Follensbee, R. A.; Geimer, R. L.; Koutsky, J. A.; Myers, G. E. 1993: Phenol-formaldehyde resin curing and bonding in steam injection pressing. II. Differences between rates of chemical and mechanical responses to resin cure. Holzforschung 47: 76–82

Follensbee, R. A. 1990: Using dynamic mechanical analysis to characterize the cure of phenolic resins. Ph.D. thesis, University of Wisconsin-Madison, USA

Follensbee, R. A.; Koutsky, J. A.; Christiansen, A. W.; Myers, G. E.; Geimer, R. L. 1993: Development of dynamic mechanical methods to characterize the cure state of phenolic resole resins. J. Appl. Polym. Sci. 47: 1481–1496

Geimer, R. L.; Christiansen, A. W. 1994: Adhesive curing and bonding: response to real time conditions. In: Proceedings of Adhesives and Bonded Wood Products Symposium, 19–21 November 1991, Seattle, WA.

Geimer, R. L.; Mahoney, R. L.; Loehnertz, S. P.; Meyer, R. W. 1985: Influence of processinginduced damage on strength of flakes and flakeboards. Research Paper FPL-RP-463. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 15 p

Geimer, R. L.; Follensbee, R. A.; Christiansen, A. W.; Koutsky, J. A.; Myers, G. E. 1990: Resin characterization. In: Maloney, T. M. (Ed.): Proceedings 24th International Washington State University, Particleboard/Composite Materials Symposium, 3–5 April 1990, Pullman, WA. Pullman, WA: Washington State Univ. pp. 65–83

Geimer, R. L.; Johnson, S. A.; Kamke, F. A. 1992: Response of flakeboard properties to changes in steam injection pressing environments. Research Paper FPL-RP-507. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 22 p.

Humphrey, P. E.; Ren, S. 1989: Bonding kinetics of thermosetting adhesive systems used in wood-based composities: the combined effect of temperature and moisture content. J. Adhesion Sci. Technol. 3: 397–413

Humphrey, P. E.; Zavala, D. 1989: A technique to evaluate the bonding reactivity of thermosetting adhesives. J. Testing and Evaluation 17: 323–328

Irle, M. A.; Bolton, A. J. 1988: Physical aspects of wood adhesive bond formation with formaldehyde based adhesives. Part II. Binder physical properties and particleboard durability. Holzforschung 42: 53–58

Kamke, F. A.; Casey, L. J. 1988: Fundamentals of flakeboard manufacture: internal-mat conditions. Forest Prod. J. 38: 38–44

Kamke, F. A.; Wolcott, M. P. 1991: Fundamentals of flakeboard manufacture: wood-moisture relationships. Wood Sci. Technol. 25: 57–71

Mizumachi, H.; Morita, H. 1975: Activation energy of the curing reaction of phenolic resin in the presence of woods. Wood Sci. 7: 256–260

Nelson, B. E. 1974: Energy considerations in a surface formed by tensile fracture of a cross-linked polymer. J. Colloid Interface Sci. 47: 595–599

SAS Institute, Inc. 1989: SAS/STAT User's Guide. Version 6. Cary, N.C.

Troughton, G. E.; Chow, S. 1980: Finger-joining kiln-dried white spruce lumber using the “WFPL method”. Forest Prod. J. 30(12): 40–49

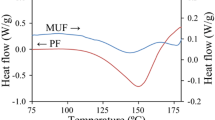

Wang, X.-M.; Riedl, B.; Christiansen, A. W.; Geimer, R. L. 1994: Differential scanning calorimetry of the effects of temperature and humidity of phenol-formaldehyde resin cure. Polymer 26: 5685–5692

Wang, X.-M.; Riedl, B.; Christiansen, A. W.; Geimer, R. L. 1995: The effects of temperature and humidity on phenol-formaldehyde resin bonding. Wood Sci. Technol. 29: 253–266

Wolcott, M. P.; Kamke, F. A.; Dillard, D. A. 1990: Fundamentals of flakeboard manufacture: viscoelastic behavior of the wood component. Wood and Fiber Science 22: 345–361

Author information

Authors and Affiliations

Additional information

This material is based on work supported by the Ministry of International Affairs, Quebec Government, the Natural Sciences and Engineering Research Council of Canada, and Laval University (Quebec City). The work was also supported by the U.S. Department of Agriculture under research joint venture agreement FP-92-1835

Rights and permissions

About this article

Cite this article

Wang, XM., Riedl, B., Geimer, R.L. et al. Phenol-formaldehyde resin curing and bonding under dynamic conditions. Wood Sci.Technol. 30, 423–442 (1996). https://doi.org/10.1007/BF00244438

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00244438