Abstract

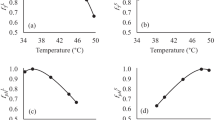

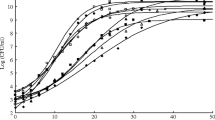

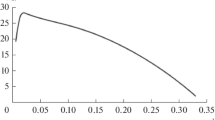

Extensive empirical research has been published on the fermentation of vegetables, but little predictive modeling of the process is available. The objectives of this study were to assess the effects of key variables involved in cucumber fermentation and to develop models for predicting the growth of Lactobacillus plantarum in pure and mixed culture fermentations. The growth medium for the studies was cucumber juice. The effects of various concentrations of lactic, acetic, and hydochloric acids and sodium chloride on growth at 30° C were determined in batch culture. Limiting conditions for growth were pH 3.37 (lower limit), 69 mm undissociated lactic acid, 150 mm undissociated acetic acid, or 11.8% NaCl. Acetic acid was stimulatory to growth at low concentrations (up to 40 mm) but inhibitory at higher concentrations. Lactic acid was more inhibitory than acetic acid, whether total or undissociated concentrations were used as the basis of comparison. A predictive equation for specific growth rate was developed, tested, and shown to predict growth of L. plantarum in batch processes reasonably well.

Similar content being viewed by others

References

Aiba S, Shocla M (1969) Reassessment of product inhibition in alcohol fermentations. J Ferment Technol 47:790–798

Aiba S, Shocla M, Nagatani M (1968) Kinetics of product inhibition in alcohol fermentation. Biotechnol Bioeng 10:845–864

Collins EB, Bruhn JC (1970) Roles of acetate and pyruvate in the metabolism of Streptococcus diacetilactis. J Bacteriol 103:541–546

Collins EB, Nelson FE, Parmelee CE (1950) Acetate and oleate requirement of the lactic group of streptococci. J Bacteriol 59:69–74

Daeschel MA, Fleming HP (1981) Entrance and growth of lactic acid bacteria in gas-exchanged, brined cucumbers. Appl Environ Microbiol 42:1111–1118

Daeschel MA, Fleming HP, McFeeters RF (1988) Mixed culture fermentation of cucumber juice with Lactobacillus plantarum and yeast. J Food Sci 53:862–864

Etchells JL, Hontz LH (1972) Suggestions for brining pickling cucumbers — the use of equilibrated brine strengths, based on the average brine-cucumber-mass temperature. Pickle Pak Sci 2:18–19

Etchells JL, Bell TA, Fleming HP, Keeling RE, Thompson RL (1973) Suggested procedure for the controlled fermentation of commercially brined pickling cucumbers — the use of starter cultures and reduction of carbon dioxide accumulation. Pickle Pak Sci 3:4–14

Fleming HP, McFeeters RF (1981) Use of microbial cultures: vegetable products. Food Technol 35:84–88

Fleming HP, McFeeters RF, Daeschel MA (1985) The lactobacilli, pediococci, and Leuconostoc: vegetable products. In: Gilliland SE (ed) Bacterial starter cultures for foods. CRC Press, Boca Raton, Fla., pp 97–118

Fleming HP, McFeeters RF, Daeschel MA (1992) Fermented and acidified vegetables. In: Vanderzant C, Splittstoesser DF (eds) Compendium of methods for the microbiological examination of foods, 3rd edn. American Public Health Association, Washington, D.C., 940 pp

Foster JW (1992) Beyond pH homeostasis: the acid tolerance response of salmonellae. ASM News 58:266–270

Ghose TK, Tyagi RD (1979) Rapid ethanol fermentation of cellulose hydrolysate. II. Product and substrate inhibition and optimization of fermentor design. Biotechnol Bioeng 21:1401–1420

Ingram M, Ottoway FJH, Coppock JBM (1956) The preservative action of acid substances in food. Chem Ind 42:1154–1163

Kuhn RH (1991) Experimental and theoretical analysis of immobilized cell behavior. PhD Thesis. North Carolina State University, Raleigh, N.C.

Lazaro MJ, Carbonell E, Aristoy MC, Safon J, Rodrigo M (1989) Liquid chromatographic determination of acids and sugars in homolactic cucumber fermentations. J Assoc Off Anal Chem 72:52–55

Levenspiel O (1980) The Monod equation: a revisit and a generalization to product inhibition situations. Biotechnol Bioeng 22:1671–1687

Luong JH (1985) Kinetics of ethanol inhibition in alcohol fermentation. Biotechnology 27:280–285

McDonald LC (1988) Factors affecting initiation of cucumber fermentation. PhD Thesis. North Carolina State University, Raleigh, N.C.

McDonald LC, Fleming HP, Hassan HM (1990) Acid tolerance of Leuconostoc mesenteroides and Lactobacillus plantarum. Appl Environ Microbiol 56:2120–2124

Potts EA, Fleming HP, McFeeters RF, Guinnup DE (1986) Equilibration of solutes in nonfermenting, brined pickling cucumbers. J Food Sci 51:434–439

SAS (1988) SAS/STAT user's guide. SAS Institute, Cary, N.C.

Tang I, Okos MR, Yang S (1989) Effects of pH and acetic acid on homoacetic fermentation of lactate by Clostridium formicoaceticum. Biotechnol Bioeng 34:1063–1074

Westcott CC (1978) pH measurements. Academic Press, New York, 171 pp

Yabannavar VM, Wang DI (1991) Analysis of mass transfer for immobilized cells in an extractive lactic acid fermentation. Biotechnol Bioeng 37:544–550

Author information

Authors and Affiliations

Additional information

Mention of a trademark or proprietary product does not constitute a guarantee or warranty of the product by the U. S. Department of Agriculture or North Carolina Agricultural Research Service, nor does it imply approval to the exclusion of other products that may be suitable

Correspondence to: H. P. Fleming

Rights and permissions

About this article

Cite this article

Passos, F.V., Fleming, H.P., Ollis, D.F. et al. Modeling the specific growth rate of Lactobacillus plantarum in cucumber extract. Appl Microbiol Biotechnol 40, 143–150 (1993). https://doi.org/10.1007/BF00170443

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00170443