Abstract:

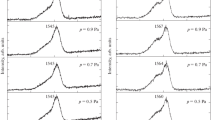

Tetrahedral amorphous carbon films have been produced by pulsed laser deposition, at a wavelength of 248 nm, ablating highly oriented pyrolytic graphite at room temperature, in a 10-2 Pa vacuum, at fluences ranging between 0.5 and 35 Jcm-2. Both (100) Si wafers and wafers covered with a SiC polycrystalline interlayer were used as substrates. Film structure was investigated by Raman spectroscopy at different excitation wavelength from 633 nm to 229 nm and by transmission Electron Energy Loss Spectroscopy. The films, which are hydrogen-free, as shown by Fourier Transform Infrared Spectroscopy, undergo a transition from mainly disordered graphitic to up to 80% tetrahedral amorphous carbon (ta-C) above a threshold laser fluence of 5 J cm-2. By X-ray reflectivity roughness, density and cross-sectional layering of selected samples were studied. Film hardness as high as 70 GPa was obtained by nanoindentation on films deposited with the SiC interlayer. By scratch test film adhesion and friction coefficients between 0.06 and 0.11 were measured. By profilometry we obtained residual stress values not higher than 2 GPa in as-deposited 80% sp3 ta-C films.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received 25 June 2001

Rights and permissions

About this article

Cite this article

Bonelli, M., Ferrari, A., Fioravanti, A. et al. Structure and mechanical properties of low stress tetrahedral amorphous carbon films prepared by pulsed laser deposition. Eur. Phys. J. B 25, 269–280 (2002). https://doi.org/10.1140/epjb/e20020031

Issue Date:

DOI: https://doi.org/10.1140/epjb/e20020031