Abstract

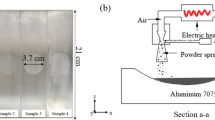

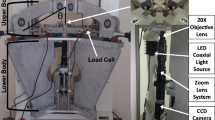

The purpose of the investigation reported here was to examine experimentally the transition behavior of a short crack in detail using surface-crack measurements with a traveling microscope and micromeasurements obtained by scanning-electron microscopy (SEM). The cyclic growth and transition of initial part-through cracks into through the thickness flaws are documented through experiments by using compact-type specimens fabricated from 7075-T6 aluminum, 2024-T3 aluminum, and mild-steel material, with a keyhole notch.

Similar content being viewed by others

References

“The Surface Crack: Physical and Computational Solutions,” Symp. Proc. of ASME Comm. for Computing in Applied Mechanics, ed. J.L. Swedlow, ASME Appl. Mechanics Div. (Nov. 1972).

“A Critical Evaluation of Numerical Solutions to the ‘Bench Mark’ Surface-Flaw Problem,” ed. J.J. McGowan,Experimental Mechanics,20 (8),253–264 (1980).

Cloud, R.L. and Palusamy, S.S., “A Summary of Critical Evaluation of Stress Intensity Factor Solutions of Corner Cracks at the Edge of a Hole,” WRC Bul. No. 276.

Smith, C.W., “Analytical and Experimental Studies of the Surface Flaw,” Experimental Mechanics,28 (2), (June 1988).

Pearson, S., “Initiation of Fatigue Cracks in Commercial Aluminum Alloys and the Subsequent Propagation of Very Short Cracks,”Eng. Fract. Mech.,7,235–247 (1975).

Suresh, S. andRitchi, R.O., “Short Fatigue Crack Propagation,”Int. Met. Rev.,19,445–476 (1984).

Lankford, J., “The Influence of Microstructure on the Growth of Small Fatigue Cracks,”Fatigue of Engineering Materials and Structures,8 (2),161–175 (1985).

Lankford, J., “The Effect of Environment on the Growth of Small Fatigue Cracks,”Fatigue of Engineering Materials and Structures,6,15–31 (1983).

Lies, B.N., Hopper, A.T., Ahmed, J., Brock, D. andKanninen, M.F., “Critical Review of the Fatigue Growth of Short Cracks,”Eng. Fract. Mech.,23 (5),883–898 (1986).

El Haddad, M.H., Topper, T.H. andSmith, K.N., “Prediction of Non Propagating Cracks,”Eng. Fract. Mech.,11,573–584 (1979).

Tanaka, K., Nakai, Y. andYamashita, M., “Fatigue Growth Threshold of Small Cracks,”Int. J. Fract.,17,519–533 (1981).

Taylor, D. andKnott, J.F., “Fatigue Crack Propagation Behavior of Short Cracks; The Effect of Microstructure,”Fatigue of Engineering Materials and Structures,4,147–155 (1981).

Brown, C.W. andHicks, M.A., “A Study of Short Fatigue Crack Growth Behavior in Titanium Alloy IMI 685,”Fatigue of Engineering Materials and Structures,6,67–76 (1983).

Grandt, Jr., A.F., Harter, J.A. and Heath, B.J., “Transition of Part-Through Cracks at Holes into Through-the-Thickness Flaws,” ASTM STP 833, 77-23 (1984).

Ramulu, M. and Taggart, R., “Subcritical Growth of Small Fatigue Cracks,” Fatigue Life: Analysis and Prediction, ed. V.S. Goel, ASM, 117–121 (1986).

Ramulu, M., “Small Fatigue Crack Growth from a Keyhold Notch,”Scripta Met.,21 (2),187–190 (1987).

Ramulu, M., “Initiation and Propagation of a Small Fatigue Crack From a Blunt Notched 7075-T6 DCB Specimen,” submitted for publication in Int. J. Fatigue.

Smith, R.A. andMiller, K.J., “Prediction of Fatigue Regimes in Notched Components,”Int. J. Mech. Sci.,20,201–206 (1978).

Smith, R.A. andMiller, K.J., “Fatigue Cracks at Notches,”Int. J. Mech. Sci.,19,11–22 (1977).

Smith, C.W., Post, D. andNicoletto, G., “Prediction of Subcritical Crack Growth from Modal Experiments,”Developments in Theoretical and Applied Mechanics,XI,167–179 (1982).

Underwood, J.H., “Stress Intensity Factors for Internally Pressurized Thick-Walled Cylinders,” Stress Analysis and Growth of Cracks, Part I, ASTM STP 513, 59–70 (1971).

Newman, Jr., J.C. andRaju, I.S., “Prediction of Fatigue Crack-Growth Patterns and Lives in Three Dimensional Crack Bodies,”Advances in Fracture Research (ICF6),3,1597–1608 (1984).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ramulu, M. Small surface and corner crack propagation in aluminum and steel alloys. Experimental Mechanics 28, 214–220 (1988). https://doi.org/10.1007/BF02317577

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02317577