Abstract

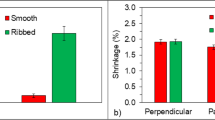

The sandwich structure of injection-moulded polypropylene parts with and without weld lines has been investigated using optical microscopy. X-ray scattering, and differential scanning calorimetry. It was found that the skin-layer thickness is strongly dependent on whether the mould is injected through one gate or through two gates. Samples containing a weld line show a much lower skin-layer thickness than samples without a weld line. This difference, however, depends strongly on the molecular weight of the polypropylene. The skin-layer thickness also varies along the flow path and decreases with increasing mould temperature. While most of the polypropylene crystallizes in the crystallographic α-modification, in the textured skin layer, some β-modification occurs. The β-crystallinity depends on the molecular weight but disappears in the weld line. X-ray investigations exhibited a bimodal crystal orientation in the skin layer, one with thec-axis oriented parallel to the flow direction, the second one with thea *-axis oriented parallel to the flow direction. The core exhibited only a weakc-axis orientation. In the skin, the metastable α1-modification was found.

Similar content being viewed by others

References

M. R. Kàntz, F. H. Newman andJ. Stigale,J. Appl. Polym. Sci. 16 (1972) 1249.

F. Altendorfer andE. Seitl,Kunststoffe 76 (1986) 47.

G. Menges, G. Wübken andB. Horn,Colloid Polym. Sci. 254 (1986) 267.

J. P. Trotignon, J. L. Lebrun andJ. Verdu,Plast. Rubber Proc. Appl. 2 (1982) 247.

E. Fleischmann, P. Zipper, A. Janosi, W. Geymayer, J. Koppelmann andJ. Schurz,Polym. Eng. Sci. 29 (1989) 835.

H. Janeschitz-Kriegl,Rheol. Acta 16 (1979) 327.

Idem, ibid. 18 (1979) 693.

B. Fisa,Polym. Compos. 8 (1987) 408.

S. Piccarolo andM. Saiu,Plast. Rubber Proc. Appl. 10 (1988) 11.

S. Piccarolo, A. Rallis andG. Titomanlio,Int. Polym. Proc. II 3 (1988) 137.

D. Singh, H. G. Mosle, M. Kunz andW. Wenig,J. Mater. Sci. 25 (1990) 4704.

W. Wenig, D. Singh, G. Botzen andH. G. Mosle,Angew. Makromol. Chem. 179 (1990) 35.

Z. Mencik,J. Macromol. Sci. Phys. 6 (1972) 101.

L. G. Berry (ed.), Powder Diffraction File (JCPDS, Philadelphia, PA 1974).

G. Wübken, Dissertation, RWTH Aachen (1974).

H. Dragaun,Progr. Colloid Polym. Sci. 62 (1977) 59.

Z. Tadmor,J. Appl. Polym. Sci. 18 (1974) 1753.

K. Pleßmann, G. Menges, M. Cremer, M. Fenske, W. Feser, C. Netze, H. Offergeld, G. Pötsch andH. Stabrey,Kunststoffe 80 (1990) 200.

E. S. Clark, J. E. Spruiell,Polym. Eng. Sci. 16 (1976) 176.

M. Fujiyama, T. Wakino andY. Kawasaki,J. Appl. Polym. Sci. 35 (1988) 29.

A. Sakthivel andA. S. Abhiraman,ibid. 29 (1984) 4257.

P. Corradini, V. Petraccone andB. Pirozzi,Eur. Polym. J. 19 (1983) 299.

G. Guerra, V. Petraccone, P. Corradini, C. De Rosa andR. Napolitano,J. Polym. Sci. Polym. Phys. Ed 22 (1984) 1029.

C. De Rosa, G. Guerra, R. Napolitano, V. Petraccone andB. Pirozzi,Eur. Polym. J. 20 (1984) 937.

C. De Rosa, G. Guerra, R. Napolitano, V. Petraccone andB. Pirozzi,J. Therm. Anal. 30 (1985) 1331.

R. Napolitano, B. Pirozzi andV. Varriale,J. Polym. Sci. Polym. Phys. 28 (1990) 139.

H. Awaya,Polymer 29 (1988) 591.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wenig, W., Stolzenberger, C. The influence of molecular weight and mould temperature on the skin-core morphology in injection-moulded polypropylene parts containing weld lines. J Mater Sci 31, 2487–2493 (1996). https://doi.org/10.1007/BF01152966

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01152966