Abstract

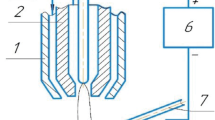

Microstructure of austenitic stainless steel weld metals is complicated by the presence of delta-ferrite and microsegregated regions rich in chromium and molybdenum, as well as other minor alloying elements such as sulphur and phosphorus at the δ/γ interphase boundaries. Detailed microstructural studies are required in order to establish correlation between various metallurgical as well as electrochemical corrosion properties with the weld metal microstructure. The conventional chemical etching technique was found to be inadequate in revealing different microconstituents. A powerful potentiostatic etching technique was used to reveal not only ferrite but also different microconstituents that had different specific electrochemical potentials at which they dissolved. This paper describes the weld metal microstructure developed by the addition of molybdenum (4.16–5.83 wt%) to type 316 stainless steel weld metals during Tungsten Inert Gas (TIG) welding with different heat inputs. © 1998 Chapman & Hall

Similar content being viewed by others

References

F. C. Hull, Weld. J. 46 (1967) 399s.

A. Garner, Corrosion 35 (1979) 108.

O. Hammar and U. Svenson, “Solidification and Casting of Metals” (The Metals Society, London, 1979) p. 401.

R. A. Farrar, in “Stainless Steels' 84” (The Institute of Metals, London, 1986) p. 336.

M. Lindenmo, ibid. p. 262.

M. J. Cieslak and W. F. Savage, Weld. J. 60 (1981) 131s.

T. G. Davey, T. G. Gooch and J. L. Robinson, Metal Construct. (1987) 545.

T. G. Gooch, Weld. Metal Fabric. April (1990) 5.

T. G. Gooch, J. Honeycombe and P. Walker, Br. Corros. J. 6 (1971) 148.

V. Cihal and M. Prazak, J. Iron Steel Inst. (1959) 360.

P. I. Marshall and T. G. Gooch, Corrosion 49 (1993) 514.

T. G. Gooch, Weld. Inst. Res. Bull. 15 (1974) 183.

R. L. Beauchamp, PhD dissertation, The Ohio State University, Columbus, OH (1966).

K. Osazawa and H. S. Engel, Corros. Sci. 6 (1966) 389.

N. D. Greene, in “Proceedings of the First International Congress on Metallic Corrosion”, (Butterworths, London, 1962) I.11, 113.

N. Suuatala, T. Takalo and T. Moisio, Metall. Trans. 11A (1980) 717.

S. A. David, Weld. J. 60 (1981) 63s.

J. A. Brooks and A. W. Thompson, Int. Mater. Rev. 36 (1991) 16.

J. C. Lippold and W. F. Savage, in “Modeling of Casting and Welding Processes”, edited by H. Brody and D. Apelian (Metallurgical Society of ASME, Warrendale, PA, 1981) p. 443.

J. A. Brooks and M. J. Baskes, in “Advances in Welding Science and Technology”, edited by S. A. David (ASM International, Metals Park, OH, 1987) p. 93.

T. P. S. Gill and J. B. Gnanamoorthy, J. Mater. Sci. 17 (1982) 1513.

A. Garner, Corrosion 35 (1979) 108.

J. A. Brooks, J. C. Williams and A. W. Thompson, Metall. Trans. 14A (1983) 1271.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pujar, M.G., Dayal, R.K., Gill, T.P.S. et al. Microstructural evaluation of molybdenum-containing stainless steel weld metals by a potentiostatic etching technique. Journal of Materials Science 33, 2691–2700 (1998). https://doi.org/10.1023/A:1004334109353

Issue Date:

DOI: https://doi.org/10.1023/A:1004334109353