Abstract

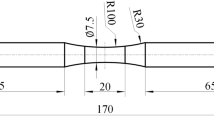

The progress of fatigue damage in type 304L solution treated stainless steel was studied by surface residual stress measurements and measurements of the formation of martensite, as determined from x-ray diffraction techniques. The specimen was subjected to tension-tension (R=0.1) cycling in air at a maximum stress σmax=422 MPa, which was approximately 160% off the yield stress. The initial longitudinal residual stress distribution was determined for 13 locations along the gage length and found to vary around −80±17 MPa (compression). After several fatigue cycles, the residual stress changes to approximately +115±17 MPa (tension). At about 7% of the life (N/N f =0.07), the variation of the residual stress along the gage length reaches a minimum. With additional cycling, the residual stress first drops, reaching a minimum at approximately 10% of the life (100±8 MPa), then increases to a maximum at between 20 and 40% of the life (125±18MPa), followed by a marked relaxation to a minimum of 90±18 MPa at approximately 65% of the life. The surface martensite content of the sample continuously increases from its initial value of around 0.6%, first slowly up to 10% of the total fatigue life, and more rapidly thereafter to final failure. On the basis of additional measurements of the residual stress and martensite content as a function of depth below the surface, surface layer hardening of austenite and martensite is suggested as the principal reason for the residual stress development.

Similar content being viewed by others

References

S. Taira,Exp. Mech. 449 (November 1973).

R. N. Pangborn, S. Weissmann, and I. R. Kramer,Scripta Metall. 12:129 (1978).

T. Sunamoto, M. Fujiwara, and K. Yanagi,Mitsubishi Tech. Rept. 7:1 (1970).

B. Cina,J. Iron Steel Inst. 177:406 (1954).

V. F. Zackay, E. R. Parker, D. Fahr, and R. Busch,Trans. ASM 60:252 (1967).

V. Weiss, K. Schroder, W. Sanford, H. Chandan, T. Kunio, D. Lal, and M. Sengupta,Final Report AMMRC CTR 73-50, 53 (1973).

A. Oda,Materials 23:279 (1974). (in Japanese)

K. Hatanaka, N. Nakagawa, H. Kawabe, and T. Yamada,Materials 19:1105 (1970) (in Japanese).

M. Ogirima and T. Hirayama,Nippun Kinzoku Gakkaishi 35:575 (1971) (in Japanese).

V. Weiss, Y. Oshida, and A. Wu,Fatigue of Engineering Materials and Structures for ICM III 1:333 (1979).

T. Goto and T. Iwamura, to be published inMaterials (1980) (in Japanese).

A. Oda and H. Miyagawa,Materials 24:118 (1975) (in Japanese).

J. Durnin and K. A. Ridal,J. Iron Steel Inst. 187:60 (1968).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Weiss, V., Oshida, Y. & Wu, A. A note on fatigue damage assessment by x-ray diffraction techniques for a 304L stainless steel specimen. J Nondestruct Eval 1, 207–213 (1980). https://doi.org/10.1007/BF00567093

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00567093