Abstract

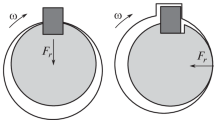

The stress-concentration factor for keyways is obtained by the electroplating method of strain analysis which was recently developed in Japan. The stresses in keyways are examined under most practical conditions. The shaft to be examined is set in a boss and fixed with a key so that the torque is wholly transmitted to the test piece through the key. To obtain the limit value for a shaft twisted only through a key, the fitting is devised so as to minimize the surface friction at the fitted portion. The results are compared to those reported previously by other authors in which local effects of the key are ignored.

Similar content being viewed by others

References

Quest, H., “Eine experimentelle Lösung des Torsionsproblems,”Ing.-Archiv,4 (5),517 (1933).

Leven, M. M., “Stresses in Keyways by Photoelastic Methods and Comparison with Numerical Solution,”Proc. SESA,VII (2),145 (1949).

Okubo, H., “On the Torsion of a Shaft with Keyways,”Quart. Jnl. Mech. Appl. Math.,3 (2),162 (1950).

Nisida, M., “New Photoelastic Methods for Torsion Problem,”Proc. Intern Symp. Photoelasticity, Pergamon Press, Oxford, 109, (1963).

Okubo, H., “Determination of the Surface Stress by Means of Electroplating,”Jnl. Appl. Phys.,24 (9),1130 (1953), “Stress-Concentration Factors for a Circumferential Notch in a Cylindrical Shaft,” Memoirs Fac. Eng., Nagoya Univ.,6 (1), 23, (1954).

Okubo, H., andSato, S., “Stress-Concentration Factors in Shafts with Transverse Holes as Found by the Electroplating Methods,”Jnl. Appl. Mech., Trans. ASME,22 (2),193 (1955).

Okubo, H., andTakai, K., “Stress-Concentration Factors in Shafts Containing Transverse Holes and Subjected to Bending,”Jnl. Appl. Mech., Trans. ASME,23 (3),478 (1956).

Okubo, H., andKikuchi, S., “Stress-Concentration Factors in Shafts,”Jnl. Appl. Mech., Trans. ASME,24 (2),313 (1957).

Okubo, H., andNozaki, N., “Grain Growth in Metals by Cyclic Stress,”Nature,180,604 (Sept. 1957);“Grain Growth and Flecking in Electroplated Copper Caused by Cyclic Stress,” Jnl. Electrochemical Soc.,105 (7), 384 (1958).

Terada, K., “Erneute Untersuchung der Formzahl für Keilnuten,”Materialprüfung,5 (10),385 (1963).

Okubo, H., Murakami, S., andHosono, K., “Microscopic Strain Distribution and Endurance Limit in Alpha-Brass,”Jnl. Inst. Metals,91,98 (1962–63).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ōkubo, H., Hosono, K. & Sakaki, K. The stress concentration in keyways when torque is transmitted through keys. Experimental Mechanics 8, 375–380 (1968). https://doi.org/10.1007/BF02326042

Issue Date:

DOI: https://doi.org/10.1007/BF02326042