Abstract

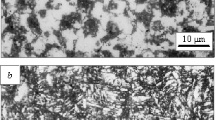

General evaluation has been applied to the products from impact-centrifugal spinning for high-speed steels of R6M5 type by chemical analysis, microprobe, x-ray diffraction, optical and scanning electron microscopy, and microhardness measurement. These products are mixtures of scaly or flaky particles (2×0.4×0.04 mm), large (2–8 mm) equiaxial fragments, and small (0.5 mm) equiaxial particles, which include spherical ones. The scales have higher contents of carbon and carbide-forming elements than do the initial materials, while the large fragments have lower ones. The elements are unevenly distributed in the scales. There are parts differing in chemical composition. These parts are formed in the scales because of concentrational inhomogeneities in the initial alloy. The thickness of a scale varied monotonically along the length, which leads to differences in cooling rate and consequently to inhomogeneities in phase composition after recrystallization.

Similar content being viewed by others

References

A. F. Belov, V. T. Musienko, Yu. G. Gol'der, and V. V. Belotserkovets, “Structural features of a nickel alloy crystallized at ultrahigh cooling rates,” Izv. Akad. Nauk SSSR, Met., No. 1, 80–85 (1980).

R. Seshadri, R. V. Krishna Rao, R. V. Krishnan, and R. M. Mallya, “Electron-beam melting and centrifugal splatquenching technique for rapid solidification of titanium alloys,” Mater. Sci.,23, No. 5, 1637–1642 (1988).

V. I. Trefilov, L. D. Kulak, and V. F. Moiseev, “Structural effects on the heat resistance of R6M5 and R6MK5 high-speed steels,” Stal', No. 3, 89–92 (1986).

H. Gager, G. Stamberger, F. Heinemann, and B. Hribernik, “Powder particle formation phenomena observed in PREP and gas atomization,” Horizons of Powder Metallurgy: Proc. of the 1986 International Powder Metallurgy Conference and Exhibition. The Future of Powder Metallurgy, P/M 86, Düsseldorf (1986), Part 1, pp. 65–70.

F. Matzer, R.-D. Locker, and F. Geglitsch, “Structure and properties of high-speed steel powder with various Nb additions atomized by different techniques,” ibid., pp. 127–132.

S. Ya. Golub, V. A. Kotko, L. D. Kulak, et al., “A new structural component in rapidly quenched tungsten—molybdenum steel,” Dokl. Akad. Nauk Ukr. SSR, Ser. A, No. 6, 62–65 (1987).

S. A. Firstov, S. Ya. Golub, L. D. Kulak, and A. S. Fomichev, “A new iron-based metastable phase formed on ultrarapid crystallization of high-alloy steels,” Fiz. Met. Metalloved.,65, No. 4, 772–775 (1988).

S. G. Glazunov and V. G. Govorov, “The VGU-2 apparatus for making spherical powders (granules) from chemically active metals and alloys,” Porosh. Metall., No. 9, 84–88 (1976).

E. I. Starovoitenko, V. T. Musienko, and S. M. Beizerov, “Calculating liquid-particle cooling rates on collision with a water-cooled copper substrate,” ibid., No. 6, 16–21 (1981).

B. P. Bewlay and B. Cantor, “Photocalorimetric cooling rate measurements on 316L stainless steel rapidly solidified by melt spinnings,” Int. J. Rapid Solidification,2, No. 2, 107–123 (1986).

K. Takeshita and P. H. Shinqu, “An analysis of the single roller rapid solidification technique,” Trans. Jpn. Inst. Met.,24, No. 7, 529–536 (1983).

G. Frommeyer and E. Vogt, “Solidification parameters, microstructures, and mechanical properties of rapidly solidified iron-based alloys,” Steel Res.,58, No. 11, 481–487 (1987).

L. Katgerman and P. J. Brink, “A mathematical model for melt-spinning of crystalline alloys,” Rapidly Quenched Metals: Proc. 4th Int. Conf., Sendal, Vol. 1 (1982), pp. 61–64.

I. R. Sare and R. W. K. Honeycombe, “Microstructural effects of splat cooling a high-speed steel,” Met. Sci.,13, No. 5, 269–279 (1979).

M. N. Hague and D. H. Kirkwood, “Microstructural variations within a splat quenched high-speed tool steel,” Int. J. Rap. Sol.,2, No. 2, 125–145 (1986).

I. V. Wood and I. V. Bee, “Structure and properties of some rapidly solidified steels,” Rapidly Quenched Metals: Proc. 4th Int. Conf., Sendal (1982), Vol. 2, pp. 1509–1514.

I. V. Wood and I. V. Bee, “Rapid solidification of steels: model and commercial alloys,” Special Steels and Materials: Proc. Int. Conf., Oxford (1983), pp. 213–220.

S. Ya. Golub, O. A. Katrus, N. N. Kuz'menko, et al., “The structural states in high-speed steel powders made by impact-centrifugal spinning,” Poroshk. Metall., No. 12, 6–10 (1990).

J. J. Rayment and B. Cantor, “The as-quenched microstructure and tempering behavior of rapidly solidified tungsten steels,” Metallurg. Trans.,12A, No. 9, 1557–1568 (1981).

Additional information

Materials Science Institute, Ukrainian Academy of Sciences, Kiev. Translated from Poroshkovaya Metallurgiya, No. 9–10 (369), pp. 1–9, September–October, 1993.

Rights and permissions

About this article

Cite this article

Khaenko, B.V., Golub, S.Y., Fomichev, A.S. et al. Composition and structure of products from high-speed steel impact-centrifugal spinning. Powder Metall Met Ceram 32, 749–755 (1994). https://doi.org/10.1007/BF00560310

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00560310