Abstract

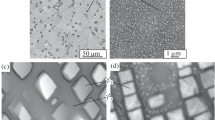

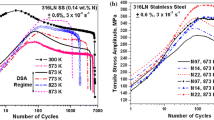

Special features of the behavior of polycrystalline nickel fatigue curves, differing by various degrees of purity and by the method of obtaining specimens have been investigated. Fatigue tests were carried out at resonance bending vibrations at a loading frequency of 2 kHz. It was established that fracture on fatigue curves is connected with the qualitative change of the dislocation structure character, i.e., the formation at high stress amplitudes of cellular structure. It is shown that the parameters of the experimental curves, approximated by short straight line segments reflect the structure of the dislocation structure, formed during cyclic tests and qualitatively interlinked with the linear dimensions of the structural elements.

Similar content being viewed by others

Literature cited

V. S. Ivanova and V. F. Terent'ev, Nature of Metal Fatigue, [in Russian], Metallurgiya, Moscow (1976).

B. A. Movchan and V. B. Shevchenko, “A macroscopic approach to dislocation structure forming during fatigue of metals”, Proc. Acad. Sci. UkrSSR, Ser. A, No. 2, 48–52 (1986).

V. B. Shevchenko, T. A. Molodkina, and B. A. Movchan, “Interconnection of dislocation structure with fatigue life in cyclic tests of nickel”, Metallogizika,9, No. 6, 60–63 (1987).

Ya. B. Fridman, Mechanical Properties of Metals [in Russian], Mashinostroenie, Moscow (1974).

D. Knoesen, S. Kritzinger, Dislocation cell boundary widths and dislocation cell sizes in deformed copper, Acta Met.,30, No. 6, 1219–1222 (1982).

M. R. Staker, D. L. Holt, The dislocation cell size and dislocation density in copper deformed at temperatures between 25 and 700°C, Ibid.20, No. 3, 569–579.

D. E. Sonon, G. V. Smith, Effect of grain size and temperature on the strengthening of nickel cobalt alloy by carbon, Trans. Met. Soc. AIME (1968),242, No. 8, 1527–1533.

A. T. Winter, O. B. Pedersen, K. V. Rasmussen, Dislocation micrcostructures in fatigued copper polycrystals, Acta Mat.,29, No. 5, 735–748(1981).

Dislocation behaviour and the formation of PSB's in fatigued copper single crystals observed by HVEM, Tabata Teizo, Fyjita Hiroshi, Hizaoka Masa-aki, Onishi Kazushi, Phil. Mag. A,47, No. 6, 841–857.

K. V. Rasmussen, O. B. Pedersen, Fatigue of copper polycrystals at low plastic strain amplitudes, Acta. Mat.,28, No. 11, 155–202(1980).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 25-28, January, 1990.

Rights and permissions

About this article

Cite this article

Shevchenko, V.B., Molodkina, T.A. & Lugovskoi, Y.F. Durability and dislocation structure of nickel at high loading frequency. Strength Mater 22, 29–33 (1990). https://doi.org/10.1007/BF00774976

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00774976