Abstract

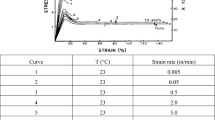

Charpy impact tests in the temperature range −100 to +20° C have been carried out on two isotactic polypropylenes (PP) having different molecular weight and their blends containing as rubbery phase an ethylene-propylene-diene terpolymer (EPDM). For fractures of brittle nature the impact data were analysed in terms of the linear elastic fracture mechanics andK c andG c were determined. This behaviour was observed for the homopolymers over the temperature range investigated, and for the blends only up to −20° C. At higher temperatures such materials showed fracture of a semiductile type with visible evidence of craze whitening around the crack tip, followed by brittle type fracture. In this case the results were analysed in terms of a ductile contribution (energy required to form the crazed area) and of a brittle one (relative to the crack propagation area) from whichG c could be derived according to a procedure proposed in the literature. Tentative interpretations of the results also on a molecular and structural basis have been given. A critical discussion of the elaboration of the semiductile fracture data proposed in the literature has also been provided.

Similar content being viewed by others

References

A. J. Kinloch andR. J. Young, “Fracture behaviour of polymers” (Applied Science, London, 1983).

G. P. Marshall, L. E. Culver andJ. G. Williams,Plastics and Polymers 75 February (1969) 75.

L. D'orazio, R. Greco, C. Mancarella, E. Martuscelli, G. Ragosta andC. Silvestre,Polym. Eng. Sci. 9 (1982) 536.

P. I. Vincent, “Impact test and service performance of thermoplastics” (Plastics Institute, London, 1971).

E. Plati andJ. G. Williams,Polym. Eng. Sci. 15 (1975) 470.

J. G. Williams,ibid. 17 (1977) 144.

L. V. Newmann andJ. C. Williams,ibid. 20 (1980) 573.

Idem, ibid. 18 (1978) 893.

Idem, J. Mater. Sci. 15 (1980) 773.

K. Nikpur andJ. G. Williams,ibid. 14 (1970) 467.

Idem, Plastics Rubber Mater. Appl. 3 (1978) 163.

P. L. Fernando andJ. G. Williams,Polym. Eng. Sci. 20 (1980) 215.

Idem, ibid. 21 (1981) 1003.

J. M. Hodgkinson, A. Savadori andJ. G. Williams,J. Mater. Sci. 18 (1983) 2319.

W. F. Brown andJ. Srawley, ASTM STP 410 (American Society for Testing and Materials, Philadelphia, Pennsylvania, 1966).

T. Casiraghi andA. Savadori,Plastics Rubber Mater. Appl. February (1980) 1.

J. D. Ferry, “Viscoelastic properties of polymers” (Wiley, New York, 1969).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Coppola, F., Greco, R. & Ragosta, G. Isotactic polypropylene/EPDM blends: Effect of testing temperature and rubber content on fracture. J Mater Sci 21, 1775–1785 (1986). https://doi.org/10.1007/BF01114739

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01114739