Abstract

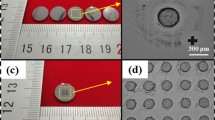

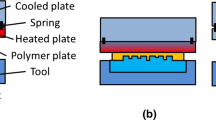

Hot embossed microstructures fabricated by laboratory and commercial environments have been studied. The laboratory process uses silicon with micropyramid patterns as the mold insert. Fine replication by using Polymethyl Methacrylate (PMMA) has been achieved. The commercial process uses electroplated nickel as the mold insert. Polyvinyl Chloride (PVC), which has a lower glass transition point than PMMA, has been used as the raw material. Fabrication results show that the laboratory process, although taking about 2 hours long per run, can successfully replicate microstructures. The commercial process which takes only 1 minute per run may be fine tuned for good replication. Atomic Force Microscope (AFM) has been used to analyze the fabricated microstructures. It is found that the root mean square (r.m.s.) roughness of PMMA is about 4 nm and that of PVC is about 10–15 nm. Defects including voids and bumps on both PMMA and PVC films have been found.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 25 August 1997/Accepted: 22 September 1997

Rights and permissions

About this article

Cite this article

Lin, L., Cheng, YT. & Chiu, CJ. Comparative study of hot embossed micro structures fabricated by laboratory and commercial environments. Microsystem Technologies 4, 113–116 (1998). https://doi.org/10.1007/s005420050109

Issue Date:

DOI: https://doi.org/10.1007/s005420050109