Abstract

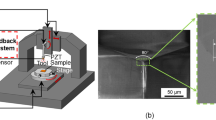

The study deals with the manufacture of diffraction grating by applying the ultraprecision microgrooving technology. Microgrooving is performed by the use of a lathe-type ultraprecision milling machine having 1 nm positioning accuracy, together with a rotating diamond cutter. As an example of microgroove, a diffraction grating with 32 768 V-shaped grooves is fabricated in a pitch of 1 μm and a depth of 0.5 μm around the circumference of copper disk of 12 mm in diameter. The high-speed rotating cutter allows the microgrooves to be sharply machined without burrs and accumulative pitch errors, taking account of cutting order. The surface roughness of machined grooves is 1 nm (Ra), which experimentally shows good optical properties.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 21 December 1998 / Accepted: 18 January 1999

Rights and permissions

About this article

Cite this article

Sawada, K., Odaka, S., Kawai, T. et al. Manufacture of diffraction grating on tiny parts by means of ultraprecision milling. Microsystem Technologies 5, 157–160 (1999). https://doi.org/10.1007/s005420050156

Issue Date:

DOI: https://doi.org/10.1007/s005420050156