Abstract

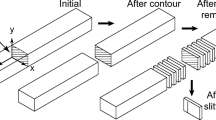

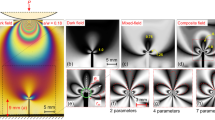

A procedure for the separation of full-field photoelastic images for use with an automated polariscope is described. Regions of background in the image are identified thus producing the boundary of the model. The shear difference method is used to calculate the components of stress along all raster lines in the image using photoelastic parameters at the boundary points to calculate the initial values of stress. Algorithms were also used to evaluate the stress components along raster lines which did not contain boundary points. A plastic template was used to evaluate the efficiency of the boundary routine. It was found that it was able to identify edges to within approximately one pixel on screen. The complete procedure for stress separation was evaluated using a stress frozen disc in compression and a turbine slot. The values of stress found using the automated polariscope with the stress-separation procedure were found to agree well with theory and with results determined using the method of Tardy compensation and manual analysis. The automated polariscope was also used to analyze three-dimensional stress components along arbitrary lines of a 3D model. A two-model slicing regime was used to analyze a strut subjected to a vertical load. This work was compared to results obtained by Frocht and Guernsey on an identical model machined from Fosterite and subjected to a higher load. Good agreement was found between the results for points away from the region of loading. Significant differences were found near to the load point, however. A finite element analysis of the same problem suggested that this was due to the effects of plasticity.

Similar content being viewed by others

References

Patterson, E.A., “Automated Photoelastic Analysis,”Strain,24,15–20 (1988).

Haake, S.J. andPatterson, E.A., “The Determination of Principal Stresses from Photoelastic Data,”Strain,28 (4),153–158 (1992).

Frocht, M.M., Photoelasticity, vol. 1, John Wiley and Sons, Inc., New York (1941).

Tésar, V., “La Photoélasticimétrie et ses applications dans la construction aeronautique,”La Science Aerienne,II,372–394 (1935).

Patterson, E.A. andWang, Z.F., “Towards Full-field Automated Photoelastic Analysis of Complex Components,”Strain,27 (2),49–56 (1991).

Wang, Z.F. andPatterson, E.A., “Use of Phase-Stepping with Fuzzy Sets for Birefringence Measurement,”Optics and Lasers in Engineering,22,91–104 (1995).

Haake, S.J., Wang, Z.F. andPatterson, E.A., “Evaluation of Automated Full Field Analysis Using Phase Stepping,”Exp. Tech.,17,19–25 (1993).

Frocht, M.M. andGuernsey, R. Jr., “Further Work on the General Three Dimensional Problem,”J. Appl. Mech.,22 (2),183–189 (1955).

Dally, J.W. and Riley, W.F., Experimental Stress Analysis, 3d ed., McGraw Hill, 1991.

Allison, I.M. andBlakemore, R.H., “The Analysis of Photoelastic Data for Stress Separations,”Recent Advances in Stress Analysis, Royal Aeronautical Society, London, 4–17 to 4–12 (1968).

Fessler, H., Marston, R.E. andOllerton, E., “A Micropolariscope for Automatic Stress Analysis,”J. Strain Anal.,22 (1),25–35 (1987).

Allison, I.M. and Nurse, P. “Automatic Acquisition of Photoelastic Data,” Proc. JBCSA Conf. Recording and Interpret. of Engin. Measure., Inst. Mar. Engrs., London, 203–207 (1972).

Takashi, M., Mawatara, S., Toyoda, Y. andKunio, T., “A New Computer Aided System for Photoelastic Stress Analysis with Structure Driven Type Image Processing,”Applied Stress Analysis, eds. T. H. Hyde andE. Ollerton, Elsevier Applied Science, London, 516–525 (1990).

Frocht, M.M., Photoelasticity, vol. 2, John Wiley and Sons, Inc., New York (1941).

Taroni, M., “Photoelastic Analysis of Jet Turboengine Parts,”10th Int. Conf. on Exp. Mech., eds. Silva Gomes et al., vol. 1, Balkema, Rotterdam, 161–166 (1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Haake, S.J., Patterson, E.A. & Wang, Z.F. 2D and 3D separation of stresses using automated photoelasticity. Experimental Mechanics 36, 269–276 (1996). https://doi.org/10.1007/BF02318018

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02318018