Abstract

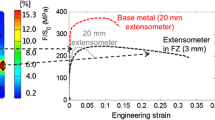

High temperature \((565^\circ C, 1050^\circ F) \) fracture toughness tests were performed on welded specimens of 1Cr-1Mo-14 V steel with different levels of mismatch between the base metal and the weld metal and the cracks lying along the fusion line. A wide range of fracture toughness values were obtained for weldments, as opposed to a unique value of JIC and a unique J-R curve typically obtained for homogeneous materials. Detailed observations of the crack path within the weldments were made to understand the wide scatter in the fracture toughness behavior. The yield strength mismatch between the base metal and the weld metal was found to directly influence the stable crack path, and hence the fracture toughness behavior. The denomination of ‘apparent fracture toughness’ was used to describe the variability of the fracture toughness in the weld region due to microstructure and mechanical property gradients. The apparent fracture toughness exhibited a minima at a fixed distance from the fusion line for a specific weld. The relative position of the fatigue precrack with respect to the fusion line and the region of low fracture toughness was also shown to influence the measured fracture toughness behavior of the specimen. A frame-work is provided for representing the weld fracture toughness behavior and the associated variability due to microstructural gradients.

Similar content being viewed by others

References

ASTM Standard E-8, (1992). Standard test method of tension testing of metallic materials. Annual Book of ASTMStandards 03.01, 130–168.

ASTM Standard E-813, (1989). Standard test method for JIC a measure of fracture toughness. Annual Book ofASTM Standards 03.01, 713–727.

ASTM Standard E-1152, (1987). Standard test method for J-R curves. Annual Book of ASTM Standards 03.01, 825–835.

Shih, C.F. and Asaro, R.J. (1988). Elastic-Plastic analysis of cracks on bimaterial interfaces: Part I - Small-scale yielding. Journal of Applied Mechanics 55, 299–316.

Shih, C.F. and Asaro, R.J. (1989). Elastic-Plastic analysis of cracks on bimaterial interfaces: Part II - Structure of small-scale yielding. Journal of Applied Mechanics 56, 763–779.

Shih, C.F., Asaro, R.J. and O'Dowd, N.P. (1991). Elastic-Plastic analysis of cracks on bimaterial interfaces: Part III - Large scale yielding. Journal of Applied Mechanics 58, 450–462.

Shih, C.F., Asaro, R.J. and O'Dowd, N.P. (1993). Elastic-Plastic analysis of cracks on bimaterial interfaces: Interface with structure. Materials Science and Engineering A162, 175–192.

Rights and permissions

About this article

Cite this article

Cretegny, L., Saxena, A. Fracture toughness behavior of weldments with mis-matched properties at elevated temperature. International Journal of Fracture 92, 119–130 (1998). https://doi.org/10.1023/A:1007409702885

Issue Date:

DOI: https://doi.org/10.1023/A:1007409702885