Abstract

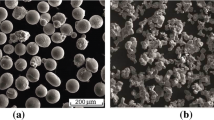

Fine and coarse alumina powder mixtures (non-additive specimen) and those containing the additive formed liquid phase during firing (additive specimen) were compacted and fired at 1400–1600°C. Liquid phase sintering proceeded markedly at 1400–1500°C and additive specimens had much higher relative density than non-additive specimens at 1500°C. As the liquid phase sintering proceeded, the open pore volume decreased abruptly, but the open pore size changed depending on the packing structure. The open pore size decreased in the specimens where the fine particles formed matrix structure, while it increased in the specimens where the coarse particles formed skeletal structure. At 1600°C all additive specimens having different mixing ratios of fine and coarse powders had similar microstructure and the same relative density of 97%. However, spherical large pores were formed and remained in all additive specimens even at 1600°C. The bending strength of those specimens was about 400 MPa.

Similar content being viewed by others

References

G. L. MESSING and G. Y. ONODA Jr, J. Amer. Ceram. Soc. 61 (1978) 1.

S. TARUTA, K. OKADA and N. ŌTSUKA, Seramikkusu Ronbunshi 96 (1988) 146.

Idem, ibid. 98 (1990) 29.

S. TARUTA, K. KITAJIMA, N. TAKUSAGAWA, K. OKADA and N. ŌTSUKA, ibid. 99 (1991) 1189.

S. TARUTA, K. KITAJIMA, N. TAKUSAGAWA, Y. TAKAGI, K. OKADA and N. ŌTSUKA, J. Mater. Sci. Lett. 12 (1993) 424.

S. TARUTA, K. KITAJIMA, N. TAKUSAGAWA, K. OKADA and N. ŌTSUKA, J. Ceram. Soc. Jpn 101 (1993) 583.

S. TARUTA, K. KAWASHIMA, K. KITAJIMA, N. TAKUSAGAWA, K. OKADA and N. ŌTSUKA, ibid. 102 (1994) 139.

E. M. LEVIN, C. R. ROBBINS and H. F. MCMURDIE, “Phase Diagrams for Ceramist” (The American Ceramic Society, Columbus, OH, 1964) p. 246.

R. K. MCGEARY, J. Amer. Ceram. Soc. 44 (1961) 513.

R. M. GERMAN, “Liquid Phase Sintering” (Plenum Press, New York, London, 1985) p. 85.

O. H. KWON and G. L. MESSING, J. Amer. Ceram. Soc. 73 (1990) 275.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Taruta, S., Takano, T., Takusagawa, N. et al. Liquid phase sintering of bimodal size distributed alumina powder mixtures. JOURNAL OF MATERIALS SCIENCE 31, 573–579 (1996). https://doi.org/10.1007/BF00367871

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00367871