Abstract

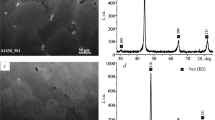

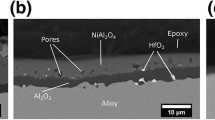

The internal oxidation of some binary Nb-Hf and several commercial Nb alloys containing Hf was studied at 1568 and 1755°C in oxygen pressures ranging from 5×10 −5 to 1×10−3 torr.The reaction kinetics were linear, suggesting that diffusion of oxygen in the substrate was not rate-controlling. The dependence of the reaction rate on oxygen pressure was linear also. Well-defined reaction fronts were observed at higher pressures and the lower temperature, whereas ill-defined fronts occurred at lower pressures and at the higher temperature. The solubility product was much higher than normally encountered in Wagnerian-type behavior and gave rise to varying solute content across the internal-reaction zone. The solute-concentration profiles (EPMA/WDS) of the matrix between particles exhibited a sigmoidal shape for well-defined reaction fronts, whereas the profiles showed a gradual decrease in solute with distance near the front for ill-defined fronts, dropping fairly abruptly at the metal/gas interface. The solute concentration never reached zero at the surface for any condition studied. In contrast to classical, Wagnerian behavior, solute continued to precipitate out after the reaction zone had passed, leading to a variation in the mole fraction of oxide in the zone. SEM/EDXA and XRD showed that precipitation occurred by the formation of “precursors” (Hf-rich regions surrounded by Hf-depleted regions), followed by precipitation of tetragonalHfO2,which in some cases transformed to monoclinicHfO2 and subsequently coarsened. The precipitate morphology varied with solute concentration, temperature, oxygen pressure, and location within the reaction zone. High temperature and high oxygen pressure favored a Widmanstätten structure, whereas low temperature and low oxygen pressure favored a spheroidal precipitate structure. Widmanstätten plates were observed to “spheroidize” at longer times, suggesting that the interfacial energy between particles and matrix was very high. The presence of a small amount of Y (0.11 w/o in C129) always resulted in spheroidal particles. It appears that Y markedly increased the particle/matrix interfacial energy. Microhardness profiles showed decreasing values with distance into the sample for some conditions and alloys but increasing values in other cases. Hardness increases in the substrate in advance of the interface showed that oxygen activity did not reach zero at the reaction front, once again contrary to classical behavior but consistent with high solubility products of the oxide. Results are analyzed in terms of oxygen-trapping by reactive solutes as noted in the literature for both lattice-parameter measurements and oxygen diffusivity studies.

Similar content being viewed by others

References

H. Inouye, inRefractory Metal Alloys, I. Machlin, R. T. Begley, and E. D. Weisert, eds. (Plenum Press, New York, 1968), pp. 165–185.

W. Mader,Proceedings of the 46th Annual Meeting of the Electron Microscopy Society of America (1988), p. 730.

W. Mader,Mat. Res. Soc. Symp. Proc. 82, 403 (1987).

M. Kuwabara, J. C. H. Spence, and M. Ruhle,Proceedings of the 46th Annual Meeting of the Electron Microscopy Society of America (1988), p. 732.

T. T. Ye, W. I. Botta, F. P. A. Labun, J. W. Christian, and G. Taylor,Acta Met. 33, 477 (1985).

A. D. Korotayev, A. N. Tyumentsev, Yu. P. Pinzhin, K. A. Markov, N. G. Minayev, and A. A. Safonov,Phys. Met. Metall. 54, 183 (1982).

H. Inouye, inProceedings of the International Symposium, Harry Stuart, ed. (AIME, 1984), p. 615.

A. D. Korotayev, A. N. Tyumentsev, Yu. P. Pinzhin, Yu. R. Kolobov, M. G. Glazunov, K. A. Markov, and N. G. Minayeu,Phys. Met. Metall. 50, 92 (1980).

R. M. Bonesteel, D. J. Rowcliffe, and T. E. Tietz,Proceedings of the International Conference on the Strength of Metals and Alloys (Trans. Japanese Inst. Metals),9, 597 (1968).

A. C. Barber and P. H. Morton,High Temperature Refractory Metals, R. W. Fountain, Joseph Malt, and L. S. Richardson, eds. (Gordon and Breach, New York, 1964), p. 391.

H. Inouye,Refractory Metals and Alloys III.: Applied Aspects, Robert I. Jaffee, ed. (Gordon and Breach, New York, 1963), p. 871.

M. S. Tsirlin,Protection of Metals 4, 186 (1968), translated fromZashchita Metallov, pp. 20–27.

M. S. Tsirlin,Protection of Metals 5, 596 (1969), translated fromZashchita Metallov, pp. 682–689.

C. Wagner,Z. Elektrochem. 63, 772 (1959).

R. A. Rapp,Corrosion 21, 382 (1965).

J. H. Swisher,Oxidation of Metal and Alloys, D. L. Douglass, ed. (ASM, Metals Park, Ohio 1971), p. 235.

J. L. Meijering, inAdvances in Materials Research, Vol. 5, H. Herman, ed. (Wiley, New York, 1971), p. 1.

G. R. Laflamme and J. E. Mortal,Acta Metall. 26, 1791 (1978).

H. J. Christ, H. Biermann, F. C. Rizzo, and H. G. Sockel,Oxid. Met. 32, 111 (1989).

A. Taylor and N. J. Doyle,J. Less-Common Met. 13, 331 (1967).

D. B. Marshall and M. R. James,J. Am. Ceram. Soc. 69, 215 (1986).

R. C. Garvie, R. H. J. Hannink, and M. V. Swain,J. Mater. Sci. Lett. 1, 437 (1982).

N. Birks and G. H. Meier,Introduction to High Temperature Oxidation of Metals (Edward Arnold, 1983), p. 99.

G. M. Ault and N. M. Burte,Oxide Dispersion Strengthening, Vol. 20 (Gordon and Breach, New York, 1968).

Alloy Digest data sheet on Columbium WC-103 dated September 1967.

G. R. Laflamme and J. E. Morral,Acta Met. 26, 1791 (1978).

E. K. Ohriner and J. E. Morral,Scripta Met. 13, 9 (1979).

W. W. Smeltzer,Oxidation Mechanisms of Metals and Associated Mass Transport, M. A. Dayananda, S. J. Rothman, and W. E. King, eds. (Met. Soc. AIME, 1987).

G. Bohm and M. Kahlweit,Acta Met. 12, 641 (1964).

J. Megusar and G. H. Meier,Met Trans. A 7A, 1133 (1976).

R. J. Lauf and C. J. Alstetter,Acta Met. 27, 1157 (1979).

E. Albert, E. Fromm, and R. Kircheim,Met. Trans. A 14A, 2117 (1983).

R. C. Frank, R. J. Lauf, and C. J. Alstetter,Met. Trans. A 13A, 539 (1982).

A. Taylor and N. J. Doyle,J. Less-Common Met. 13, 313 (1967).

A. H. Heuer, N. Claussen, W. M. Kriven, and M. Ruhle,J. Am. Cer. Soc. 65, 642 (1982).

I.-W. Chen and Y.-H. Chaio,Acta Met. 31, 1627 (1983).

I.-W. Chen and Y.-H. Chaio,Advances in Ceramics 12, 33 (1984).

G. M. Wolten,J. Am. Cer. Soc. 46, 418 (1963).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Corn, D.L., Douglass, D.L. & Smith, C.A. The internal oxidation of Nb-Hf alloys. Oxid Met 35, 139–173 (1991). https://doi.org/10.1007/BF00666504

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00666504