Abstract

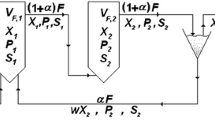

Research on gas-solid fluidized bed fermenters has been performed since the early 1980's. This new type of fermentation system is applicable in the production of volatile substances with inhibiting effects upon the bioreaction and in the production of specific metabolites in a solid-state mode. The fluidized bed fermenter system provides excellent mass and heat transfer and allows fermentation to take place under water-reduced conditions [1].

This paper delivers the theoretical results achieved the production of ethanol by Saccharomyces cerevisiae in a fluidized bed fermentation system including recirculation of the fluidizing gas and coolers for ethanol recovery. The influence of the parameters governing process control, i.e. reactor productivity, ethanol concentration in the gas phase and in the condensate, and the specific energy consumption, are shown. The energy requirement is compared to that of conventional systems for ethanol production.

Similar content being viewed by others

Abbreviations

- C′ E kg/m3 :

-

EtOH concentration cooler

- C E kg/m3 :

-

EtOH concentration yeast

- C /* E kg/m3 :

-

inhibiting EtOH concentration

- c p,E kJ/kg · K:

-

specific heat capacity EtOH

- c p,W kJ/kg · K:

-

specific heat capacity water

- c p,G kJ/kg · K:

-

specific heat capacity inert gas

- C S kg/m3 :

-

substrate concentration

- dr s−1 :

-

dilution rate

- e 1 kJ/dm3 eth.:

-

specific energy consumption

- e 2 :

-

specific energy consumption

- e 3 kJ/dm3 eth.:

-

specific energy consumption

- e add kW/m3 :

-

additional energy flow

- e E kW/m3 :

-

energy flow EtOH

- e G kW/m3 :

-

energy flow inert gas

- e W kW/m3 :

-

energy flow water

- e tot kW/m3 :

-

total energy flow

- e /* tot kW/m3 :

-

total energy flow

- Δh E kJ/kg:

-

evaporation enthalpy EtOH

- Δh W kJ/kg:

-

evaporation enthalpy water

- m DY kg:

-

mass of dry yeast

- \(\dot m\) E,in kg/s:

-

EtOH mass flow inlet

- \(\dot m\) E,out kg/s:

-

EtOH mass flow outlet

- \(\dot m\) W kg/s:

-

water input by substrate

- Δ \(\dot m\) W kg/s:

-

partially evaporated water

- \(\dot m\) S kg/s:

-

mass flow of substrate

- M E kg/kmol:

-

molecular weight EtOH

- M W kg/kmol:

-

molecular weight water

- M S kg/kmol:

-

molecular weight of substrate

- M sol kg/kmol:

-

molecular EtOH-water solution

- P kg/(m3·s):

-

EtOH reactor productivity

- P E Pa:

-

EtOH vapor pressure

- P W Pa:

-

water vapor pressure

- P tot Pa:

-

total pressure

- T F °C:

-

fermenter temperature

- T f °C:

-

feed temperature

- T C °C:

-

cooler temperature

- X 1 E kmol/kmol:

-

EtOH concentration coller

- X E kmol/kmol:

-

EtOH concentration yeast

- X /* E kmol/kmol:

-

inhibiting EtOH concentration

- Y E,in m3/m3 :

-

EtOH concentration inlet

- Y E,out m3/m3 :

-

EtOH concentration outlet

- Y W,in m3/m3 :

-

water concentration inlet

- Y W,out m3/m3 :

-

water concentration outlet

- V G m3/s:

-

inert gas flow rate

- V bed m3 :

-

volume of the bed

- ε dm3 :

-

voidage of the bed

- φ kg/kg:

-

humidity of the yeast

- γ E :

-

EtOH activity coefficient

- γ W :

-

water activity coefficient

- v max s−1 :

-

maximum conversion rate

- ϱ e kg/m3 :

-

EtOH density (vapor)

- ϱ e,f kg/m3 :

-

EtOH density (fluid)

- ϱ g kg/m3 :

-

inert gas density

- ϱ w kg/m3 :

-

water density (vapor)

- ϱ sol kg/m3 :

-

density of EtOH-water solution

- ϱ y kg/m3 :

-

yeast density

References

Bauer, W.; Kunz, B.: Solid-state fermentation in food industry in biochemical engineering. Stuttgart: Gustav Fisher Verlag 1987

Röttenbacher, L.: Entwicklung und Modellierung eines Gas/Feststoff Wirbelschichtfermenters für die Erzeugung von Ethanol mit S. cerevisiae. Diss., Techn. Univ. Hamburg-Harburg (1985)

Kolbe, B.; Gmehling, J.: Thermodynamic properties of ethanol+water. II. Potentials and limits of G E models. Fluid Phase Equilibria 23 (1985) 227–242

Maiorella, B.; Wilke, R.; Blanch, H. W.: Alcohol production and recovery. In: Ghose, T. K.; Fiechter, A.; Blakebrough, N. (Eds.): Advances in Biochemical Engineering, vol. 20, pp 44–92. New York: Springer 1981

Moebus, O.; Teuber, M.; Reuter, H.: Growth of S. cerevisiae in form of solid particles in a gaseous fluidized bed. Kieler Milchwirtschaftliche Forschungsberichte 33 (1981) 3–23

Akao, T.; Okamoto, Y.: Cultivation of microorganism in airsolid fluidized bed. Proc. Int. Conf. Fluidization, May/June 1987, Kashidojima 961–967

Bauer, W.: A comparison between a conventional submerged culture fermenter and a new concept gas/solid fluid bed bioreactor for glutathion production. Can. J. Ch. E. 64 (1986) 561–566

Röttenbacher, L.; Bauer, W.: Modelling a solid-state fluidized bed fermenter for ethanol production with S. cerevisiae. Bioprocess Engineering 2 (1987) 25–31

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Beck, M., Bauer, W. Energy balance of ethanol production with a gas-solid fluidized bed fermenter. Bioprocess Engineering 4, 123–128 (1989). https://doi.org/10.1007/BF00369761

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369761