Summary

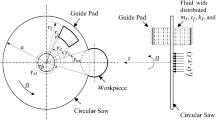

The origin and measurement of residual stresses and their effect on the transverse stability of circular saws are discussed, with emphasis placed on nondestructive stress analyses, their limits of application, and their possible adaptation to the measurement of residual stresses in circular saws. Saw stability variations can be computed once the stress distribution is known. Evaluation of the X-ray diffraction technique and the ultrasonic and magnetic methods were considered for this purpose.

Alternatively, saw stability can be related to resonance and bending stiffness measurements in specific modes. However, the state of stress cannot be inferred from these tests. For saw stability prediction, measurement of the state of stress is more essential than are direct stiffness measurements.

Similar content being viewed by others

References

Abuku, S., Cullity, B. D. 1971. A magnetic method for the determination of residual stress. Experimental Mechanics 11 (5):217–223.

Bagchi, D. K., Cullity, B. D. 1967. Effects of applied and residual stress on the magnetoresistance of nickel. J. Appl. Physics 38 (3):999–1000.

Baldwin, W. M. 1949. Residual stresses in metals. Proceeding, American Society for Testing Materials 49:539–583.

Barret, C. S., Massalski, T. V. 1966. Structure of metals. McGraw-Hill Book Co., New York, 466–484.

Barz, E. 1953. Untersuchungen an Kreissägen für Holz, Fehler-und Spannungsprüfverfahren. Forschungsbericht Nr. 51 des Wirtschafts-und Verkehrsministeriums Nordrhein-Westfalen. Köln und Opladen: Westdeutscher Verlag.

Barz, E. 1957. Fertigungsverfahren und Spannungsverlauf bei Kreissägeblättern für Holz. Forschungsberichte des Wirtschafts- und Verkehrsministeriums Nordrhein-Westfalen Nr. 360. Köln und Opladen: Westdeutscher Verlag.

Barz, E., Berger, A. 1960. Holzbereitungswerkzeuge. Mitteilungen der Deutschen Gesellschaft für Holzforschung. Heft Nr. 45. Stuttgart DGfH.

Barz, E. 1960. Prüfgeräte für den Richt-und Spannungszustand von Kreissägeblättern. Holz Roh-Werkstoff 18 (1): 19–25.

Barz, E. 1962. Der Spannungszustand von Kreissägeblättern und seine Auswirkungen auf das Arbeitsverhalten. Holz Roh-Werkstoff 20 (10): 393–397.

Barz, E. 1963. Vergleichende Untersuchungen über das Spannen von Kreissägeblättern mit Maschinen und mit Richthammern. Holz Roh-Werkstoff 21 (4): 135–144.

Barz, E. 1965 Zur Frage der Eigenspannungen in scheiben- und bandförmigen Werkzeugen. I. Mitteilung: Zerstörungsfreie Ermittlung von Eigenspannungen bei scheiben-und bandförmigen Trennwerkzeugen. Holz Roh-Werkstoff 23 (10): 412–419.

Barz, E., Münz, U. 1968. Prüfung und Beurteilung des Richt-und Spannungszustandes bei Kreissägeblättern für die Holzbearbeitung. Holz Roh-Werkstoff 26 (5): 170–175.

Benson, R. W. 1968. Development of nondestructive methods for determining residual stresses and fatigue damage in metals. Contract No. NAS8-20208. Propulsion and Vehicle Engineering Laboratory, George C. Marshall Space Flight Center, Huntsville, Alabama.

Berolzheimer, C., Best, C. 1959. Thin circular saw blades. Forest Prod. J. 9 (11): 404–412.

Bolstadt, D. A., Davis, R. A., Quist, W. E., Roberts, E. C. 1963. Measuring stress in steel parts by X-ray diffraction. Metal Progress, 88–92.

Bolstadt, D. A., Quist, W. E. 1965. The use of a portable X-ray unit for measuring residual stresses in aluminum, titanium and steel alloys. Advances in X-ray Analysis 8: 26–37.

Christenson, A. L. (ed.) 1960. Measurement of stress by X-ray. Society of Automotive Engineers Technical Report No. 182, SAE, Inc., New York.

Clotfelter, W. N. 1972. Marshall Space Flight Center, Huntsville, Alabama. Personal communication.

Cullity, B. D. 1967. Element of X-ray diffraction. Addison-Wesley Reading, Mass., 431–451.

Denton, A. A. 1966. Determination of residual stresses. Metallurgical Rev. 11 (101): 1–23.

Dugdale, D. S. 1963a. Effect of internal stress on elastic stiffness. J. Mech. Phys. Sci. 11: 41–47

Dugdale, D. S. 1963b. Effect of internal stress on the flexural stiffness of dises. Int. J. Engineering Sci. 1: 89–100.

Dugdale, D. S. 1963c. Measurement of internal stress in dises. Int. J. Engineering Sci. 1: 383–389.

Dugdale, D. S. 1964. Indentation of strips with flat dies on a flat anvil. Int. J. Production Res. 3 (2): 141–151.

Dugdale, D. S. 1965. Flexure tests for revealing internal stress in discs. Int. J. Engineering Sci. 3: 1–8.

Dugdale, D. S. 1966a. Theory of cireular saw tensioning. Int. J. Production Res. 4 237–248.

Dugdale, D. S. 1966b. Stiffness of a spinning dise clamped at its centre. J. Mech. Phys. Solids 14: 349–356.

Dugdale, D. S. 1968. Flexure of thin plates containing internal stress. Int. J. Engineering Sci. 6: 239–249.

Frick, R. P., Gurtman, G. A., Meriwether, H. D. 1967. Experimental determination of residual stresses in an orthotropic material. J. of Materials 2 (4): 719–748.

Friebe, E. 1970. Steifheit und Schwingungsverhalten von Kreissägeblättern. Holz Roh-Werkstoff 28 (10): 349–357.

Firestone, F. A., Frederick, J. R. 1946. Refinements in supersonic reflectoscopy polarized sound. J. of the Acoustical Soc. of America. 18 (1): 200–211.

Gause, R. L. 1967. Ultrasonic analysis of cold-rolled aluminum. Nondestructive testing: Trends and techniques. Proceedings of the Second Technology Status and Trends Symposium, NASA SP-5082: 31–42.

Greaves, R. W., Kirstowsky, E. C., Lipson, C. 1945. Residual stress study. Proceedings, Society for Experimental Stress Analysis 2 (2): 44–58.

Hanslip, R. E. 1952. Residual stress in surface-hardened oil field pump rods. Proceedings, Society for Experimental Stress Analysis 10 (1): 97–112.

Heyn, E. 1914. Internal strains in cold wrought metals and some troubles caused thereby. J. of the Institute of Metals 12: 1–37.

Hiendelhofer, K. 1951. Evaluation of residual stresses. McGraw-Hill, Inc. New York.

Khasdan, S. M. 1956. Tensioning of cireular saws. Derev. Prom. 5 (9): 15–17.

Macherauch, E. 1966. X-ray stress analysis. Experimental Mechanics 6: 140–153.

Mack, D. R. 1962. Measurement of residual stresses in disks from turbine-rotor forgings. Proceedings, Society for Experimental Stress Analysis 19 (1): 155–158.

McKannan, E. C. 1967. Ultrasonic measurement of stress in aluminum. Nondestructive testing: Trends and techniques. Proceedings of the Second Technology Status and Trends Symposium NASA SP-5082: 43–54.

Meins, W. 1963. Geräuschuntersuchungen an Kreissägeblättern für die Holzbearbeitung. Dissertation. T. H. Braunschweig.

Mote, C. D., Jr. 1963. Effect of inplane stresses on the vibration characteristics of clampedfree dises. Ph. D. Dissertation, Univ. of Calif., Berkeley.

Mote, C. D., Jr. 1964. Circular saw stability. Forest Prod. J. 14 (6): 244–250.

Mote, C. D., Jr. 1965. Free vibration of initially stressed circular disks. Trans. ASME 87 (B): 258–264.

Mote, C. D., Jr. 1967. Natural frequencies in annuli with induced thermal membrane stresses. Trans. ASME 89 (B): 611–618.

Mote, C. D., Jr. 1970a. Stability of cireular plates subjected to moving loads. Journal of the Franklin Inst. 290 (4): 329–344.

Mote, C. D., Jr. 1970b. Discrete element models for the stres and vibration analysis of plates. University of California Forest Products Laboratory, Service Report No. 35.01.77.

Mote, C. D., Jr., Nieh, L. T. 1971. Control of circular dise stability with membrane stresses. Experimental Mechanics 11 (11): 290–298.

Neff, H. 1960. Röntgenographische Spannungsmessungen an gehärteten Stählen. Sonderdruck aus ‚'ATM”, Lieferung 298.

Nisida, M., Hond, M., Hasunuma, T. 1956. Studies of plastic deformation by the photo-plastic method. Proceedings, Sixth Japanese National Congress of Applied Mechanics, 137–140.

Nye, J. F. 1947. Discussion on the measurement of internal stresses. Symposium on Internal Stresses in Metals and Alloys. Institute of Metals, London, 382.

Orowan, E. 1948. Classification and nomenclature of internal stresses. Symposium on Internal Stresses in Metals and Alloys. Institute of Metals, London, 47–59.

Pahlitzsch, G., Rowinski, B. 1966a. Über das Schwingungsverhalten von Kreissägeblättern, Erste Mitteilung: Bestimmung und Auswirkung der geometrischen Form und des Vorspannungszustandes. Holz Roh-Werkstoff 24 (4): 125–134.

Pahlitzsch, G., Rowinski, B. 1966b. Zweite Mitteilung: Ermittlung und Auswirkungen der kritischen Drehzahlen und Eigenfrequenzen der Sägeblätter. Holz Roh-Werkstoff 24 (8): 341–346.

Palermo, P. M. 1963. An evaluation of the hole-relaxation method of determining residual stresses. Report 1742, David Taylor Model Basin, Washington 7, D. C.

Prokeš, S. 1972. Comparison of methods for measuring tension of saw disks. Drevo. 27 (7): 181–183.

Rembowski, J. L. 1958. Theory for the calculation of the tangential residual stress distribution in eurved beams. Proceedings, Society for Experimental Stress Analysis 16 (1): 195–198.

Richards, D. G. 1945. A study of certain mechanically-induced residual stresses. Proceedings, Society for Experimental Stress Analysis 3 (1): 40–61.

Riney, T. D. 1957. Photoelastic determination of the residual stress in the dome of electron tube envelopes. Proceedings, Society for Experimental Stress Analysis 15 (1): 161–170.

Riparbelli, C. 1950. A method for the determination of initial stresses. Proceedings, Society for Experimental Stress Analysis 8 (1): 173–196.

Rollins, F. R. 1959. Study of methods for nondestructive measurement of residual stresses, Technical Report 59-561, Wright Air Development Division, Wright-Patterson Air Force Base, Dayton, Ohio.

Rollns, F. R. 1961. Ultrasonic methods for nondestructive measurement of residual stresses, Technical Report 61-42, Part I, Wright Air Development Division, Wright-Patterson Air Force Base, Dayton, Ohio.

Rollins, F. R., Kobett, D. R., Jones, J. L. 1963. Study of ultrasonic methods for nondestructive measurement of residual stress, Technical Report 61-42, Part II, Wright Air Development Division, Wright-Patterson Air Force Base, Dayton, Ohio.

Rollwitz, W. L. 1969. Magnetoabsorption techniques for measuring material properties. Part II. Measurement of residual and applied stress. Technical Report 66-76, Air Force Materials Laboratory, Wright-Patterson Air Force Base, Dayton, Ohio.

Rollwitz, W. L. 1972. Southwest Research Institute, San Antonio, Texas. Personal communication.

Sachs, G. 1940. Practical metallurgy, Amer. Soc. Metals, Cleveland, Ohio.

Sachs, G., Espey, G. 1941. The measurement of residual stresses in metals. Iron Age. September 18, 63–71; September 25, 36–42.

Schaal, A. 1955. Industrielle Anwendungsmöglichkeiten der röntgenographischen Spannungsmessung. Archiv für das Eisenhüttenwesen. 26 (8): 445–447.

Stakhiev, Yu, M. 1965. Rolling machine for circular saws. Derev. Prom. 14 (2): 28.

Sugihara, H. 1952. Some problems of circular saw blades, especially on tensioning. Wood Res. Inst. Kyoto University, 4: 1–32.

Szymani, R. 1972a. Residual stresses and tensioning of cireular saws for wood. University of California Forest Products Laboratory, Service Report No. 35.01.94, Progress Report No. 1.

Szymani, R. 1972b. Evaluation of X-ray technique for residual stress analysis in circular saws. University of California Forest Products Laboratory. Technical Report No. 35.01.94, Progress Report No. 2.

Szymani, R. 1973. Potential of ultrasonie methods for residual stress analysis in cireular saws. University of California Forest Products Laboratory. Technical Report No. 35.01.94, Progress Report No. 3.

Taylor, A. 1961. X-ray metallography. John Wiley & Sons, Inc., New York.

Tokareik, A. G., Polzin, M. H. 1952. Quantitative evaluation of residual stresses by the stresscoat drilling technique. Proceedings, Society for Experimental Stress Analysis 9 (2): 195–207.

Treuting, R. G., Lynch, J. J., Wishart, H. B., Richards, D. G. 1952. Residual Stress Measurements. Amer. Soc. Metals, Cleveland, Ohio.

Tverdynina, M. M. 1966. Tensioning control of the circular saws by the deflection of saw rim. Derev. Prom. 15 (3): 12–14.

Yakunin, Ya, K., Khasdan, S. M. 1957. Stability and vibration of circular saw dises during operation. Derev. Prom. 6 (8): 11–14, 6 (9): 14–15.

Author information

Authors and Affiliations

Additional information

The authors would like to express their gratitude to Professor R. M. Bragg, Department of Material Science and Engineering, U. C. Berkeley, and to Dr. R. L. Gause and Mr. W. N. Clotfelter, Marshall Space Flight Center, Huntsville, Alabama, for valuable suggestions and permission to use X-ray and ultrasonic equipment. The authors are also grateful for the financial support of the project from the University of California Forest Products Laboratory; the California Cedar Products Company, Stockton; the California Saw, Knife and Grinding Company, San Francisco; Sun Studs, Roseburg, Oregon; Weyerhaeuser Company, Tacoma, Washington; and McIntire-Stennis Funds.

Rights and permissions

About this article

Cite this article

Szymani, R., Mote, C.D. A review of residual stresses and tensioning in circular saws. Wood Science and Technology 8, 148–161 (1974). https://doi.org/10.1007/BF00351369

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00351369